| |

|

|

|

|

|

|

|

|

|

|

After

keeping fishrooms for 30 years, I tried a wide variety of

aquarium stands - generally the metal

put-together stands from Home Improvement Stores that

run about $80 and rust out in about 7-10 years.

I am getting to where I would like my fishroom stands

to be more permanent than that, and needed

stands that were:

- Heavy wood that would be stable and that could be painted

to waterproof them.

- That you could make at home with a cheap saw, electric

drill and tape measure, ideally

in just a couple hours, without need for a

shop to do cut-outs, etc.

- That would be incredibly strong and stable, able to hold 2

rows of 55 gallon tanks easily.

- And that were made of only 2x4s, 3/4' plywood for the

shelves under the tanks, some 4" x 1/2" panels,

some screws and maybe a bolt or two. Cost must be

minimal.

I did find that stand, and here is how you make it.

If you have any questions about anything here that

does not seem clear, please email selectaquatics@gmail.com,

and I will get right back to you!

Lastly since this

involves power tools and a period of sobriety I am aware may be

challenging for some

fishkeepers I know, you will need to set aside a

weekend to do this properly. I have made 10 of these

racks so far, and found that spending the first day

cutting the wood, then painting it, then putting

the rack together the next day worked best. These racks

have worked well for me. Study the

design carefully, and understand how and why these

racks work before cutting any wood.

However, if you

injure yourself, or you have trouble with the rack for any

reason, Select Aquatics

can in no way be held responsible! Good luck!

Greg Sage, Owner, Select Aquatics

|

|

|

|

|

| |

|

This pair of

racks were built fall 2014, and these are

very sturdy and stable. However, that extra strength

comes with a price- each rack is slightly longer due

to the double legs, than a standard rack with single

supports. But a standard rack requires cut outs needing

wood shop tools. This rack can be done by one person

in their fishroom, and this rack will never sway or tilt.

|

|

|

|

|

|

|

|

Tools and materials You

Will Need:

- A circular hand saw that

can make straight cuts

- A drill that can handle drill bits and three inch wood

screws

-If possible, a second drill to drill pilot holes, then just switch

drills to put screws in

(This is a big time saver as each rack takes around 60

screws)

- A tape measure and pencil

- I use duct tape to hold joints together before pilot holes

are drilled, and screws

are put in.

- 2x4s, enough to build the size stand you are looking for.

(See below)

- 42 inches of a 4" x 1/2" wood slat also available at any lumber

store

- Two 4'x2' pieces of 3/4" plywood for the shelf bottoms

- A box of 3" wood screws

- 20-25 1.25" wood screws to attach plywood shelving to rack,

and braces to back.

- Paint and paintbrush

- A drill bit to make pilot holes for the 3 inch

screws, and screwhead bit*

- Paint and paintbrush

* I found that using a "star" type head, rather than a Phillips,

was quicker and easier |

|

|

|

|

Step 1:

Draw Up What you will Need

Each Rack

will have 22 pieces of wood, regardless of the rack size. How

big you want

the rack to be will come down to the lengths of these pieces.

There will be:

4 Legs

4 Rails (The long horizontal pieces)

4 Front to Back horizontal Supports (or 8, if you want to

double up - see below)

8 Vertical leg Supports - 4 for each shelf- 4 cut for bottom

shelf, 4 for top

2 4 x 1/2" diagonal back supports

For Example, the natural colored wood stand below has 2

shelves, the tank footprint

is 13x48 inches. The first shelf is 31 inches off the ground,

the top shelf is 63 inches.

The dimensions for that stand are:

4 Legs - 62 inches each

4 Rails - 52 inches each

4 Front to back Supports - 10 inches each

4 Vertical leg supports for bottom shelf - 30 inches each

4 Vertical leg supports for top shelf - 28.5 inches each

Two 21 inch 4 x 1/2" diagonal back supports

Keep in mind to purchase 2x4s that are 8 feet long, and then

plan how to cut

them so that you make most efficient use of the wood.

To increase the depth of the rack, simply increase the length

of the Front and Back Supports.

A rack can

be as long as 8 feet, but if you go over 4 feet, you will need

to

provide for a middle set of legs to break up longer than a 4

foot span,

Or the rack may not be able to hold the weight of the aquariums. |

|

|

|

|

|

|

|

| |

|

|

|

Raw Materials

Because it

is best to paint the wood before it is

built into a project, I would build a stand over 2 days.

Day 1 the wood was measured and cut, sorted and then

painted to dry overnight. Day 2 involved putting the

rack together, and removing tanks from any racks the

new ones were replacing, then, getting the new rack

set up with tanks, etc. |

|

|

|

|

|

|

| |

|

|

|

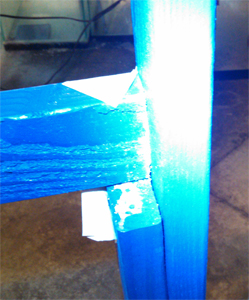

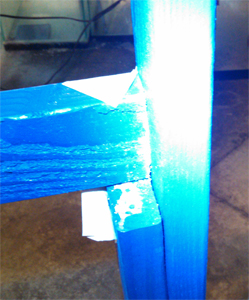

Attaching Lower

Supports

Attach pieces cut

to height of first shelf

to the bottom of each leg as shown. The Rails

will be set and attached as shown, with

two 3 inch screws coming in from the

other side. To put the bottom rail on the legs

so it is supported, before screws have

been put in, I will duct tape the joint

as shown on one end, then attach

and screw the other side in as shown in

the pic to the left.

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

So now you will have the two

sides of the rack

constructed, with the rails for the first shelf

attached, but the two structures are not

connected to one another. Be sure when you

attach the rail ends to the legs you will need

a left and a right half, so place the rails on

the legs correctly. |

|

|

|

|

|

|

|

|

The Front to back pieces are

now put in, and

they are screwed in as shown, as well as 2 screws

going in from the back side. Be careful putting in

screws at these areas - it is easy to have them hit

one another. |

|

|

|

|

|

|

|

|

This is a better pic of another stand with

similar construction. In this case I put in two

front to back pieces at every joint thinking it

would provide extra stability. It may have,

all of the stands I have made since have had

just one. Then, as you can see, the upper

supports are attached next. I used 4 screws

for each support. |

|

|

|

|

|

|

|

|

At this

point, with the upper supports attached,

you should have a structure that looks like this. |

|

|

|

|

|

|

|

|

The top Rails and Front and Back pieces are

attached in the same manner as the lower

shelf was.

The

secret to this design is that the wood distributes

the weight by resting against other 2x4s, which are

held in

place by a second set of 2x4s that provide stability.

The screws do very little weight bearing. |

|

|

|

|

|

|

|

|

This

shot shows how at least two screws are going

in to hold each of the Front to Back cross pieces.

As well, you can see how without paying attention,

These 3 inch nails can easily hit one another inside

the wood.

|

|

|

|

|

|

|

|

|

Once the rack structure is

all put together,

at both top corners on the backside of the rack,

attach a piece of 4" x 1/2" panel wood, each

piece about 18- 21" long., with the ends cut to

fit as shown. These braces are essential. |

|

|

|

|

|

|

|

|

Here is a stand just

completed, and the 3/4" plywood has

been attached with the 1.25 inch wood screws. On this rack,

the plywood was cut to extend out and a provide a small

work area. This rack is the one on the left in the top pic.

The piece of 3/4" plywood still needs to be attached to to

the top. |

|

|

|

|

|

|

|

|

And this is

the final result! |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|