|

This is an Automatic Water Change System that Requires:

No Pumps

No drilling

No Air

Little Maintenance

Because of this:

You never need to risk breaking a tank to drill it.

Moving

tanks around is no problem.

System

can be modified easily to add or delete tanks.

This system will not:

Pass water between tanks

Spread diseases or pathogens

Water being added is:

Oxygenated

Proper temperature

Evenly distributed between tanks

However, the system requires:

-Being gravity (siphon) dependant, tanks must be at least 12”

off ground.

-You will need a nearby sink to both fill and drain, OR a

reservoir and a drain

holding temperature controlled, aged water. (Where you will then

need to

pump the water from the reservoir)

-Using water from the tap will work without dechlorination, as

you will only

be adding up to about 20% tank volume at a time.

-Obtaining and Working with PVC and PVC glue

Pros-

-No drilling tanks, leaking drain portholes, pumps, motors or

moving water

with air or powered means that can fail

-No need to turn anything off or disrupt fish to change water

-No need to add dechlor

-Can do changes regularly, at any percentage, as often as you

like

-What used to take me 3-4 hours on Saturday of carrying buckets

I

can now do daily, with no effort, in 40 minutes.

-Temperature shock is avoided with frequent, small changes

-You can spend more time cleaning tanks and doing other work

-No backflow siphon issues

-Water does not mix between tanks

-Fish are healthier, bigger, and breed more frequently.

-Plants do far better

-Periods of inactivity (vacations, etc.), are less stressful on

the fish because water changes continue.

-Diseases are far less frequent (I may have had a case of ich

once

in 5 years, and nothing else).

-Though I cannot drain water from individual tanks with the

system,

I

can easily fill whenever I clean by turning on that zone for as

long as I need manually. I can turn off the other tanks in that

zone

if I do not want to change any water.

Cons-

-If you need to empty a tank you must still do it by hand

-

You are committed to the water parameters that come from your

water supply.

unless a tank is taken off of the water change system, it must

do well at the pH

and hardness of your source water.

-At times there can be a fair amount of working with PVC glue

-Tanks must be observed regularly to restart a drain siphon if

it stops

-You should be aware of internal water pressure within the PVC

system

(Do not turn water on full when valves are open if water is

turned off

into tanks.)

__________________________________________

Changes made to my fishkeeping to best

adapt to the system.

1. My fishroom is primarily bare bottomed tanks. The system does

not

clean up mulm or vacuum the bottoms of tanks

2. Most of my fish are well adapted to the water quality that

comes

from my tap. My Ph is about 7.4, Hardness is low, at 90ppm.

3. I am experiementing with doing a 4 minute change daily,

rather

than 10 minutes every other day (which equals about 15% in 10

gal. tanks

from my tap).

4. I am not concerned when they are occasionally overfed, but

have strived

to keep the bottoms free from mulm buildup. However, water

changes can be

frequent enough to prevent ammonia buildup, encouraging the

cultivation of

infusoria for fry- so I leave a thin layer of mulm in my fry

tanks

(particularly the smaller egg layers). When a tank appears

stressed,

I

first look at temperature, knowing that water quality will less

likely be

a

factor.

5. Whenever I do any work that involves draining a tank more

than an inch or

two I always ensure that the drain siphon has not stopped

working.

________________________________________

Materials needed

for installation:

Pad and paper- everything is written out before hand

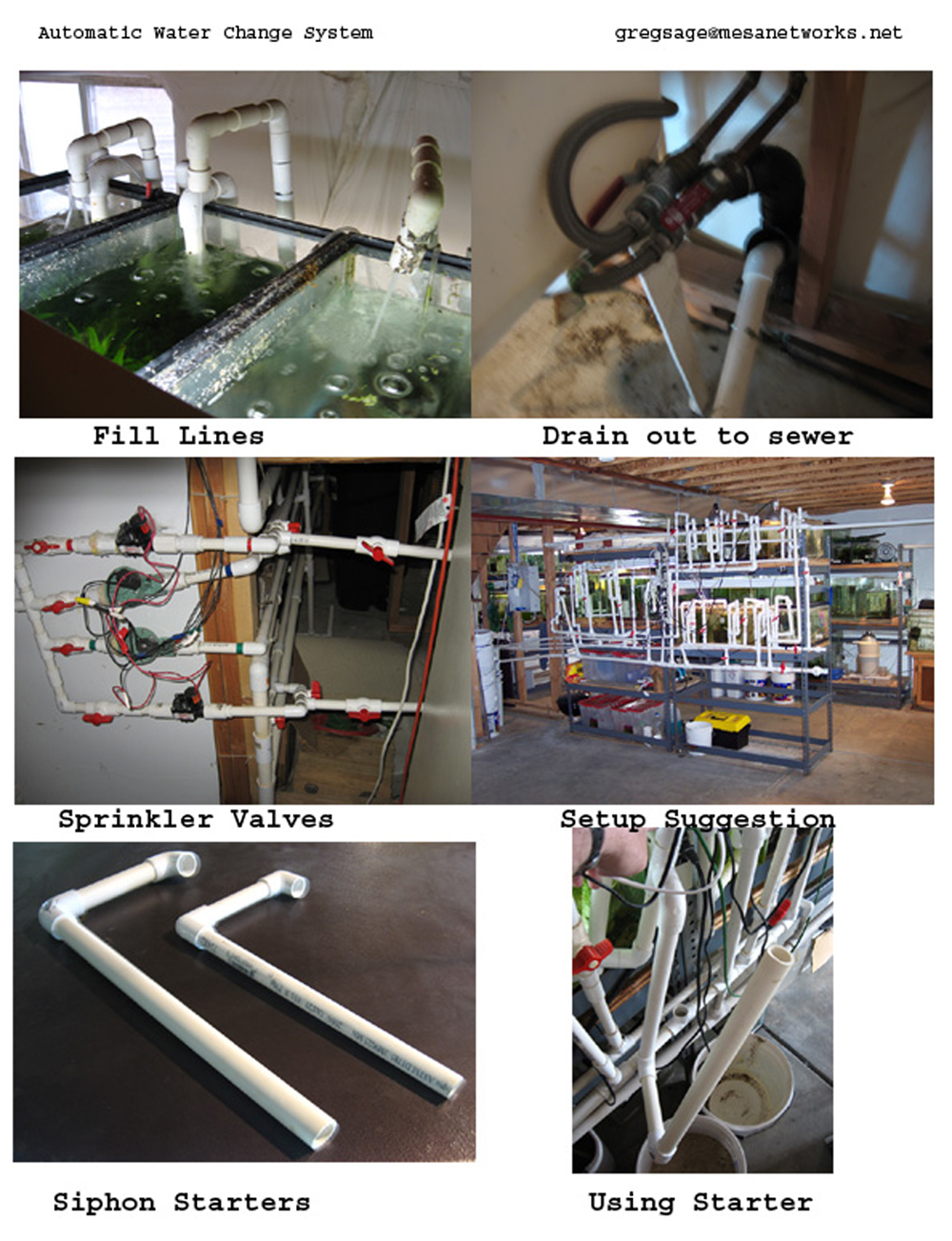

A 2, 4 or 6 zone control box and sprinkler valves - depending on

the size of

your room, that are available at any Home Depot, Lowe’s etc. A

lawn sprinkler

control box costs about $30, and a valve for each zone is about

$10.

System can be done entirely manually with lines splitting into

separate zone

lines from sink, and changes are then done by turning on water

by hand, rotating

from zone to zone. You must be sure to have a zone open when

turning the water on,

and open next zone before turning current zone off so that PVC

setup isn’t forced

to hold entire tap water pressure (though it should be able to).

PVC- get to know the guys at Home depot. They will wonder what

you are doing after

buying up all their ½” valves half a dozen times. Your planning

on paper will tell

roughly how much PVC, fittings and valves you will need. PVC

materials are bizarre

cheap. 10 feet of half inch PVC costs under $2.00.

You will be using ½ inch PVC tubing (for all filling lines), ¾

inch (for all drain

setups from each tank) and 1 inch section lengths that will

collect water from the

tank drains and connect to the main sink drain.

I highly recommend at least one hand-held PVC cutter (about

$10.00).

PVC glue- I just use the simple clear stuff in the gold can. Use

your own judgement.

You MUST glue all fill lines, for they hold pressure from the

tap. I don’t glue most

drain lines once the water has drained from the tanks, and I

prefer knowing it can be

torn down or changed easily, but I do encounter occasional

dripping. However, drain

setups at each tank MUST be glued until the water gets to the

main drain, or air will

get into the setup where it should not, and the siphon can stop.

PVC glue runs about

$2.50 a can.

Angles, Ts, Valves etc.- Each tank’s fill and drain line setups

will require a certain

number, then multiply out. They are also affordable-

“contractor” packs- packs of 10-

are also generally under $2. Valves are the greatest expense.

Each tank has one, and a

few more valves will control where water goes based on the size

of your setup. They run

about $3 apiece. As a rule (depending on your room) you’ll be

using 90 degree pieces

in ½”, ¾” and 1” sizes. Also connectors, tees, and end caps and

in all three sizes,

reducers will be 3/4” to ½” and 1” to ¾”, but you will only

using ½” valves. Again,

try to determine how many you will need ahead of time to keep

visits to the hardware

store to a minimum.

Electrical Ties- I use these to help hold and stabilize the

lines against the racks

and each other. 8 or 11 inch ties work best, and they can be

connected to one another

to create longer pieces if needed. Bags of 100 are about $9.

You will also need:

About a weekend to do this, depending on the number of tanks you

have.

A ventilated area

A drill with a 16th inch or so bit

A Tape measure

2 pairs of pliers to easily disconnect joints not yet glued

Clothes you don’t mind getting wet, and possibly stained with

PVC glue.

Best way to do it:

Be aware that it will be 1 week after building this system

before being able to use it.

The PVC glue must be fully cured and dissipated before water

running through the PVC

cleans off the glued joints. Introduced water pressure will move

any glue residue into

the tanks with the fish. I have lost fish that died as a result

of my running water

into a tank through a line containing new glue that hadn’t dried

thoroughly.

Steps:

1. Ensure

that all tanks are where you want them to be. Have tanks placed

to provide

easy access behind them, and set up in straight lines when

possible. The bottom tanks

must be at least 12 inches from the ground and above the drain

used to collect the water

that drains out.

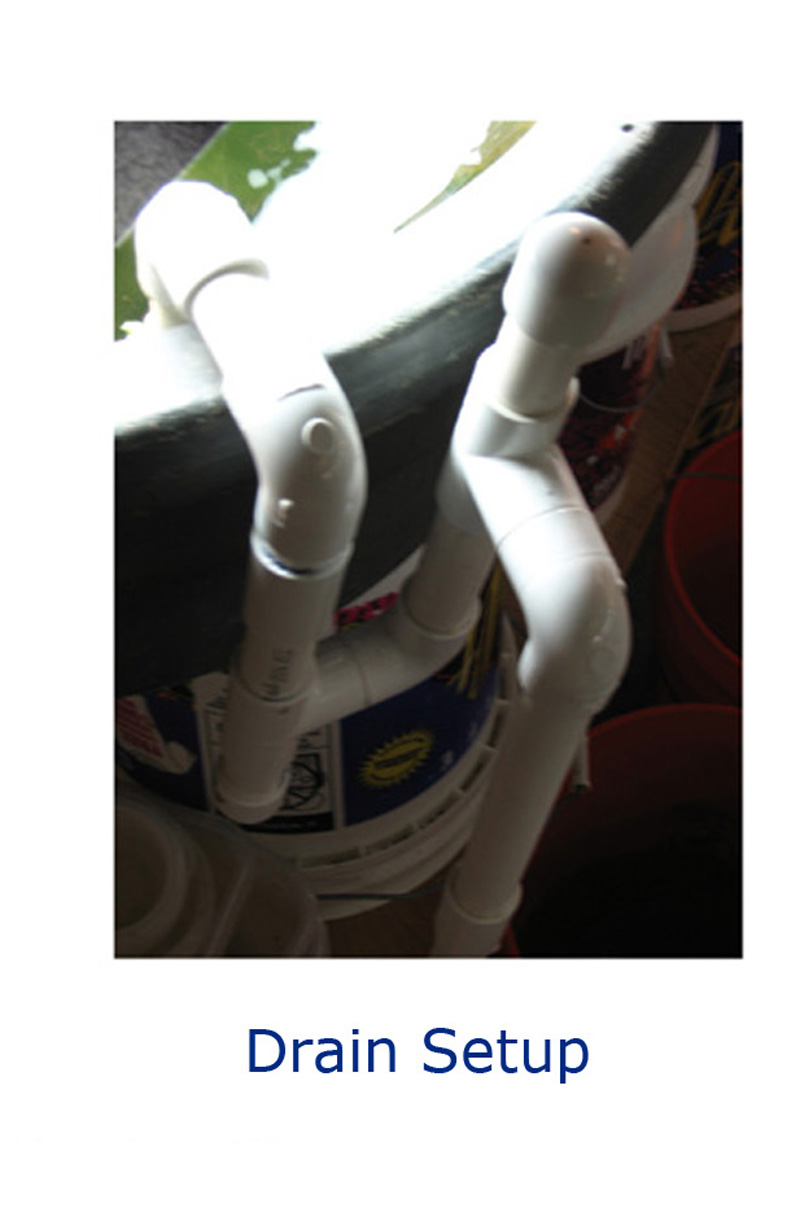

2. Build all of the drain setups

for each tank from ¾’ inch tubing. Observe attached

drain siphon setup photos. Keep in mind the size of the tank

each will be used on,

and where the main drain line will be located that it will be

draining into. All fill

lines will be ½ inch and drain lines ¾ inch. You want to be sure

that water never fills

faster than it can drain. All drain lines collect to a 1 inch

line so that it will not

back up.

You will see that where the drain T is placed within the drain

setup apparatus determines

the water level in the tank. Always keep at least 2 inches

“headroom” from the surface of

the water to the top of the tank to prevent overflowing if the

drain setup loses its

siphon (from having worked on the tank where it was drained

down, etc.)

I built one for each size of tank (all 10s, 20s etc.), didn’t

glue them, took them each

back apart, then made each piece multiplied out to number of

tanks. Then I put them

together and glued them, then set aside.

The most time intensive part is drilling all of the little holes

into the in-tank drain

ends so that any fry are not sucked out.

The connection where this drain setup drains into the 1” drain

line will NEVER be glued

into the 1” line. You will need to use this joint to restart the

siphon if it stops.

(which happens very rarely- maybe once every other month on one

or two tanks in my 60

tank fishroom, and can always be traced to my working on it or

it being drained down

too far, and I didn’t check it afterward)

3. Now build the ½” fill lines for

each tank. Drill a 16th inch hole into the middle of

each end cap. Each fill PVC line must be made specifically for

each tank. Keep in mind

where the light sits, so that water flows into tank

unobstructed. I use the white plastic

honeycomb light grating to cover tanks that need to be covered,

they don’t obstruct water

flow from the fill lines.

Do not make them so that drilled caps sit in the water, water

should enter from cap

ideally 2-3” from surface to provide aeration and prevent back

siphoning into other

tanks when the flow stops.

4. Glue fill

line setups together, keeping knobs so that they are easy to

access and

knobs can move freely from open to fully closed.

5. Begin to conceive where the ½”

fill line from the sprinkler valve back at

the sink will be placed, and how the fill line will best lay

against the back

of the tanks and attach to the rack, while next to the drain

setups.

-I installed my fill lines first, then had the drain sit lines

against them. See

attached top rack PVC photo.

-Keep in mind that the fill lines will hold pressure, so keep

turns, etc. with

the fill lines to a minimum.

___________________________________________

Keep in mind that everything you do until step 10 will be

disconnected and

re-built outside or in a well ventilated area to be glued

together in sections.

The sections will then be be glued together in the fishroom as

they are put in

their final place on the tanks.

___________________________________________

6. Lay out 1” drain line tubing

behind tanks and begin to put in the 90 degree

angles etc. to fit the lines to the angles of your room.

-There needs to be a 1” line for each row of tanks that will

then drain into

the single 1” line out to the sink drain.

-Temporarily attach this line to the rack, or support it as you

will want it.

(Nothing will be permanently attached until after everything is

glued in a

ventilated area and brought back to the fishroom. I do not glue

the 1” drain

lines, so they can be roughly put in place.)

-If you are really organized and somewhat good at this, gently

slope the 1”

drain line toward the sink drain from far point of the room.

This will help to

avoid any standing water within the setup.

7. Determine how you will tap into

the sink drain line.

I put a “Y” piece in below the fishroom sink so that both the

sink and the fishroom

water go out of the house together.

In one fishroom, instead of draining to the city sewer I drained

into a plastic

garbage can with a pump that then moved the water out into the

yard and garden.

8. Run the fill line from the sink

to the sprinkler valves mounted nearby.

Hook valves up to control box.

Have fun and be creative with all the new PVC you just bought,

and end up with a

line from each valve to a designated portion of the fishroom.

9. Hang the already made drain

lines from the tanks.

The tanks of each row will drain into their own 1” drain line

that will then T

into the 1” line that goes to the sink drain. Put a tee into the

1” line, then

you will need a 1” to ¾” reducer to connect the ¾” individual

tank setups into the

1” line. Do not allow a tank to somehow drain into a tank below.

Each tank row drains

into the same 1” drain line that goes down to the main drain

line and out to the main

drain. This will prevent water mixing between tanks. (This can

be seen on photo of back

of tanks, attached)

To prevent vacuums within the 1” drain lines from developing,

causing siphoning to start

where it is not intended, I put a T into the lowest 1” drain

lines with an open ¾” line of

PVC rising straight up to above the room’s water level, allowing

air to enter the drain

lines as they head to the end drain. This opens up the flow,

prevents siphoning and helps

keep water from building up within the drain system. In my room

of 6 zones, I have put in

4 of them spaced equally throughout the room.

_________________________________________________

10. Begin cutting tubing for both

fill and drain lines that will be connected to already

built fill and drain setups and put it all together. Build as it

will be in final form

with light hoods placed in, etc. Do not glue anything yet.

11. Divide up when finished into

sections that can be brought to a well- ventilated area

to glue. Obviously, keep all angles of each connection as it

should be- I have used a marker,

putting a line over the joints that needed to be angled, then

simply matched them up when

outside. Completed drain setups can be left on tanks, they will

never be glued into drain

lines for they need to be disconnected to start or restart the

siphon.

______________________________________________

PVC glue and its fumes are toxic to fish. Always allow any

freshly glued area to dry

thoroughly- days, not hours, before running water into the tanks

from newly glued areas.

_______________________________________________

12. Glue sections together. Let dry

and air out THOROUGHLY. Keep all valves in the open

position to assist air flow through the PVC when drying.

*Nearly all of the times I have encountered problems with drain

siphons has been due to spots

I’d missed gluing at this stage of the process.

Be aware to keep structure in small enough pieces when finally

placed on the tanks in the

fishroom so that it can be put together and glued easily,

without any force or tension.

13. Carry back into fishroom and

place on tanks, aware of where sections need to be

connected. Do one section at a time, make sure every connection

is glued that needs to be

when putting the system together. See attached back of rack

photo.

_________________________________________________________________________________

Remember:

It is only PVC. As long as you have one or two connectors and a

little glue you can cut a line

(As long as the water is off. This may sound stupid. I’ve done

it. More than once.) and change

whatever you’d like. Put it back together and voila, good as

new.

_________________________________________________________________________________

14. When all is in place and glued

marvel at your work and try to forget about it for at least

3

days, a week is best. Leave all valves on tanks open to assist

air flow through system.

Then after a wait of 3-7 days…

15. Make a “Siphon Starter”.

Observe siphon starter photos attached. You will need two

pieces of ¾” PVC, one maybe a foot long, the other about 18”.

Connect with a 90 degree elbow,

then put 2nd 90 degree elbow on other end of shorter piece.

16. Start the siphon in each drain

setup structure for each tank:

To start the drain siphon loop for each tank: Be sure the tank

is filled slightly above where

the T in the drain setup will drain down to the 1” drain line.

Gently connect the 90 degree elbow

(because it will need to come off quickly) on the shorter end of

your siphon starter over end of

the line going down to the 1” main drain line. Place finger over

hole in top of drain setup and

inhale firmly to begin siphon in outer loop. Then connect to the

1” drain line placed to take water

from that tank while trying to get as little water on your shoes

as possible. See attached Siphon

Starter photos.

17. Now go around the room and

check that all of the valves on the fill lines into each tank

are

open about halfway. ALWAYS be aware to keep system “open”.

Closing off many or all of the valves

could cause a crack or a blowout in the system over time.

18. Now the fun begins. GENTLY turn

on the water about 1/3 to half the strength you want to

eventually expect to use.

You are looking for:

-

Leaks, Drips

-

Water going where it should not. This sounds silly, but if you

have more than 10 or 20 tanks,

you may find that a drain line taking too many tanks too soon is

causing another tank in an odd

place to fill rather than drain. In my room of about 60 tanks I

had two of those spots to fix.

-

How evenly is water being distributed? Begin to turn some fill

valves up, some down depending

on flow to adjust the flow into each tank. If no immediate

problems, turn up flow of water

slightly, continuing to adjust. Tanks closest to water source

will be at greater flow than tanks

later in line and tend to fill faster, etc.

-

Watch for some tanks filling faster than others. This could be

water going in, but it is more

likely that the siphon hasn’t started properly in the drain

setup, and needs to be restarted.

-

Water flow from the nozzles hitting light hoods, causing any

problems.

-

Watch for water going into tanks causing too much disruption,

and adjust accordingly.

19. Let it run for up to 10

minutes, possibly adding an antichlorine agent- you do not yet

know how much water is actually being added. Gradually increase

the pressure to the desired flow,

watching for any of the problems listed above.

20. Turn off. Then set timers at

control box. I would keep the water changes gradual at first-

I

have been doing 15% every other day for 4 years (about 10

minutes on a 10 gallon tank with

water pressure at about 2/3rds full strength.). At first, I

would start at about half that,

increasing as you wish, keeping in mind that too much can bring

chlorine and chloramine issues.

UPDATE- Since this article was written, I have since

settled into a 15% water change daily.

At some point you may want to find out exactly how much water is

being changed. To do this I

divert the fill stream from a tank at about mid distance from

the sink into a bucket, measuring

the amount of water in the bucket at specific time intervals,

keeping track of where the knobs

are placed where the water is turned on. Full strengh with both

hot and cold turned up could

end up too hot, and far more water than you need.

Maintenance: This for me is simply

looking for puddles, locating the leak and fixing it,

usually by replacing or simply gluing the offending joint. As

well, due to joints weakly

glued initially or missed having been glued altogether, a drain

setup will lose its siphon-

in my room it will happens on one tank about every 3 months.

Because the water levels

in each tank are set where the "T" is placed going down to the

1" drain line, a 15% addition

during water change will not overflow the tank, but can be

spotted and fixed before the next

water change.

UPDATE- Since this article was

written I have seen that the eventual loss of siphon on a tank

can often be spotted days before it actually happens. But more

often, I have had problems from

turning off a tank to restart the siphon at a later time,

(because I had drained the tank working

on it, or it looked liked it needed to be restarted) and then

forgetting about it- resulting in

the tank going a period without water changes. So I have put a

1/4 inch strip of red electrical

tape on every tank, marking where the water level of that tank

is when the drain siphon is working

properly. When a drain line begins to lose its siphon it will

sometimes go gradually- over a few

days, and the tape will show the water level rising in the tank.

If it has been turned off or is

not filling for any reason, the water level in the tank will

then evaporate down.

The room now has close to 1000 ft. of tubing. I have tanks from

each zone spread throughout

the room (all 30’s fill at same time wherever they are located

in the room, etc). This is simply

because the system evolved over time, and I did not move tanks,

as I probably should have, to

accommodate the system. That is not the easiest, nor the most

sane way to do it. Hopefully,

yours will be set up more cleanly and less prone to the

occasional repair. With my system of

hundreds of connections and joints, I fix about 5-6 a year,

usually in one or two quick

sessions.

On the rare times a drain siphon loses its siphon it is usually

because I had worked on the

tank and drained the tank too far, then forgot to restart the

siphon. When this happens it

will not drain- Obvious because the tank is fuller than the

other tanks. (the reason for the

“headroom” mentioned earlier.) If you are only changing 10% or

15% each change, then the

tank will not overflow.

Sometimes a joint had simply been forgotten to be glued, and at

other times it may just

need to be restarted. Of dozens of weekends and vacations of up

to a week away I have never

had a siphon lose its siphon when I was gone.

When I have had any problems:

Over the 6 years of using this or a similar system, problems

have been rare, but here

is a rundown:

1. A sprinkler valve once malfunctioned, and a section kept

refilling and draining,

eventually killing all of the fish in that zone. That was the

single biggest disaster I

have ever had. I now spend the extra buck and get better quality

valves. There has never been

another instance similar to that. Preventable.

***** UPDATE- When putting in the sprinkler controller, most

will provide an option for a

valve that will come on before zone 1 and turn off just before

the last zone finishes. This

way the longest a broken valve can cause the water to flow into

tanks is the maximum length of

time all of teh ziones you are using take to fill- preventing

losses. Today I use that

"master valve" setup, and would never consider the system being

set up without it.

2. Twice I lost tanks of fish to water changing too soon after a

repair and fumes wiped

out the fish. Not all fish were affected. In both instances 3 or

4 tanks were affected,

but in both instances it was only the tiger limias that all

died. Again, preventable.

3. Twice I put water in that was too warm, but I was only

changing 15%. I would never have

known, except that in both instances I wiped out my A. toweri

that seem particularly

sensitive to warm water, while affecting no one else. Also

preventable.

And the last of those problems happened over 4 years ago. Good

Luck!

Greg Sage

selectaquatics@gmail.com

selectaquatics.com

Back to Downloads Page

Home

Species for Sale

Fishkeeping Tips

Receiving and Shipping Fish

|

|